CO₂ Sandcasting Process

Cost-effective, versatile, and ideal for complex geometries — discover our CO₂ sand casting capabilities.

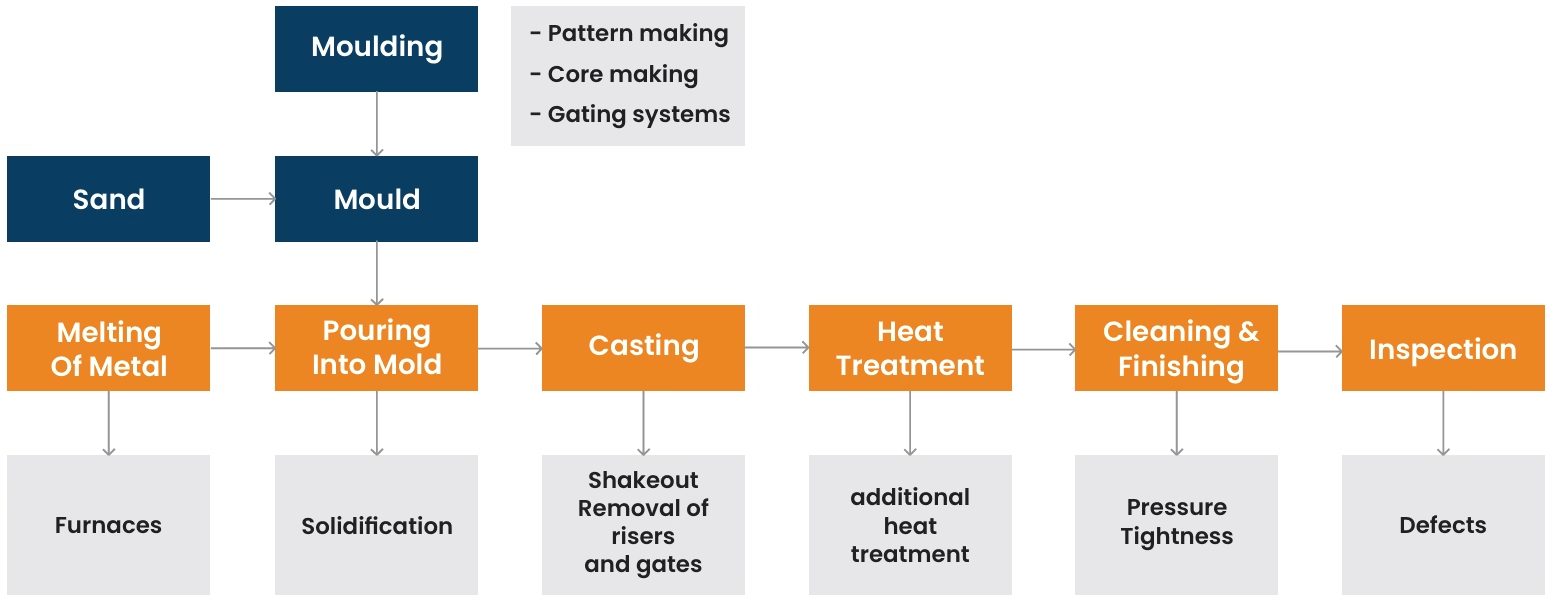

Sand Casting Process

Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex metal parts that can be made of nearly any alloy. Because the sand mold must be destroyed to remove the part, called the casting, sand casting typically has a low production rate. The sand casting process involves the use of a furnace, metal, pattern, and sand mold. The metal is melted in the furnace and then ladled and poured into the cavity of the sand mold, which is formed by the pattern. The sand mold separates along a parting line, and the solidified casting can be removed.

Route To Accuracy

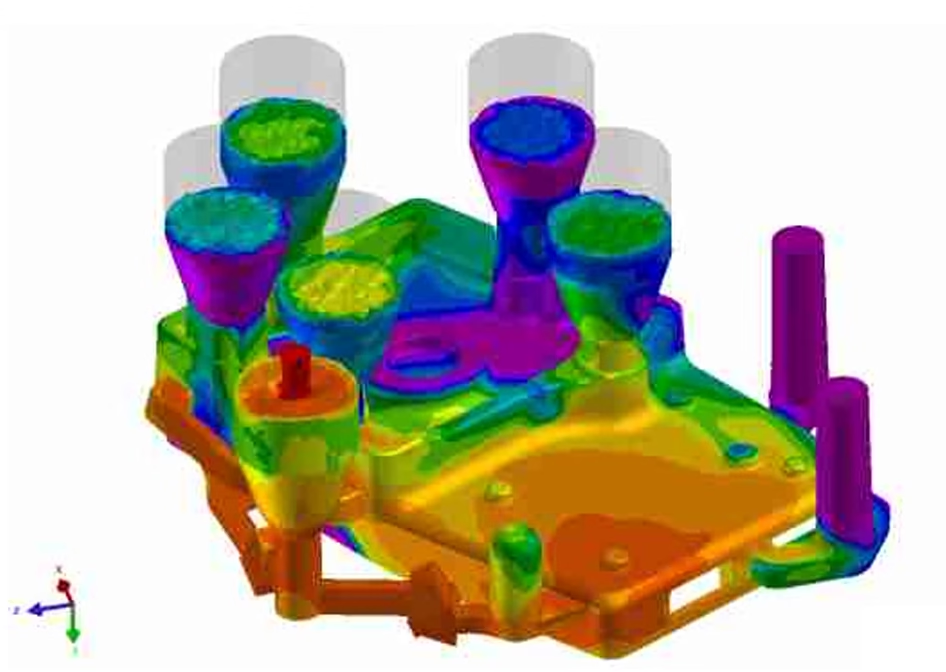

Simulation Facility

At MRIDINI, we provide a Simulated Casting facility for challenging jobs, utilizing tools to simulate filling, solidification, and cooling analyses. Defects in sand castings can often be traced back to the filling stage.MRIDINI has extraordinary accuracy in predicting metal flow, providing insight into the performance of the rigging system and resulting fill defects. Oxide formation and cold shuts are accurately tracked and located in the final casting. Risers are sized and placed at hot spots, while advanced solidification and shrinkage analysis allow for a final, optimized design to be reached in even the most challenging manufacturing environments.

Machining & Testing Facilities

In addition to having an in-house machining facility for proof-machining components, Mridini Casting LLP can also arrange for the outsourcing of finished goods. We are also capable of performing tests such as chemical and mechanical tests, hydro pressure tests, and more.

Advantages

The CO2 casting process is ideal where speed and flexibility are the prime requirements. Molds and cores of various sizes and shapes can be molded by this process. This process has many advantages compared to other forms of casting. Some of them are as follows:

- Compared to other casting methods, cores and molds are strong.

- Reduces fuel costs since gas is used instead of other costly heating elements.

- Reduces the large requirement for mold boxes and core dryers.

- Provides great dimensional tolerance and accuracy in production.

- Moisture is completely eliminated from the molding sand.

Applications

Engineered for a wide range of industrial uses — from structural components to complex machinery parts.

Pump & Valve Industries

Heavy Machine

Marine

Steel Plants

Gears

Blowers & Impellers

Mining Machines

Power Plant

Railways

What Our Clients Say About Us

We’ve built long-standing partnerships with engineers, procurement heads, and manufacturers who rely on us for consistent quality, technical precision, and timely delivery.

“Working with Mridini has been a game-changer for our supply chain.”

Their team provided material guidance that improved both casting performance and cost-efficiency. We now rely on them for all our centrifugal castings.

- A. Mehta, Global Pump Manufacturer

“Precision, consistency, and no follow-ups — exactly what you want from a casting partner.”

Mridini's ability to maintain tight tolerances across batches saved us from costly rework. Their quality systems are impressive.

- S. Reddy, Rail Component OEM

“We were struggling with irregular deliveries and surface defects until we switched to Mridini.”

Since then, our rejections have dropped significantly and our lead times are better controlled. Highly recommended.

R. Sharma, Industrial Valves Exporter