Centrifugal Catalog

Precision casting method for high-integrity, cylindrical components with exceptional density and structural reliability.

One of India’s Leading Centrifugal Casting Manufacturers

Mridini Castings L.L.P. is among the best Centrifugal casting manufacturers in India and we are specialized in manufacturing all types of Ferrous & Non Ferrous Centrifugal Casting, according to customers’ requirements. Also, we can offer fully finished and ready-to-use Machined components.

The materials we use in our products include Ferrous &Non ferrous metals including Carbon steel, H13, GCR15, Ni-Hard, Heat resisting Hk Grades, SS310, 20MnCr5, HCHCr., as well as other superior quality materials.

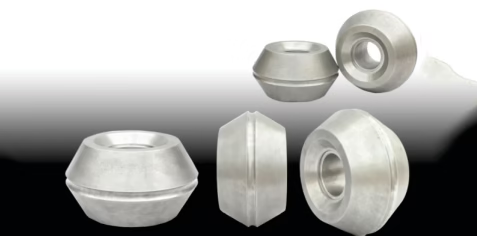

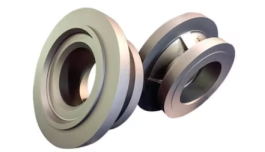

Our Products

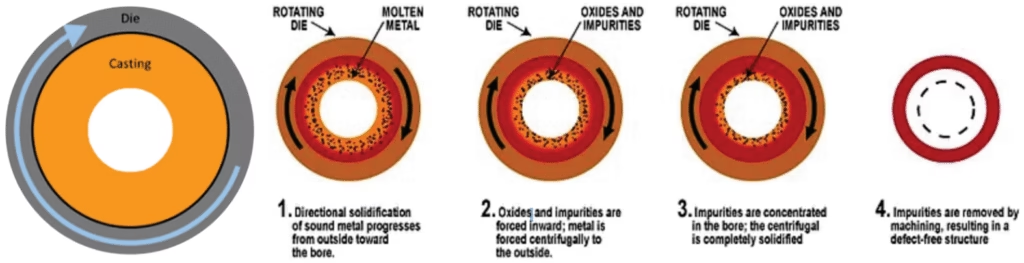

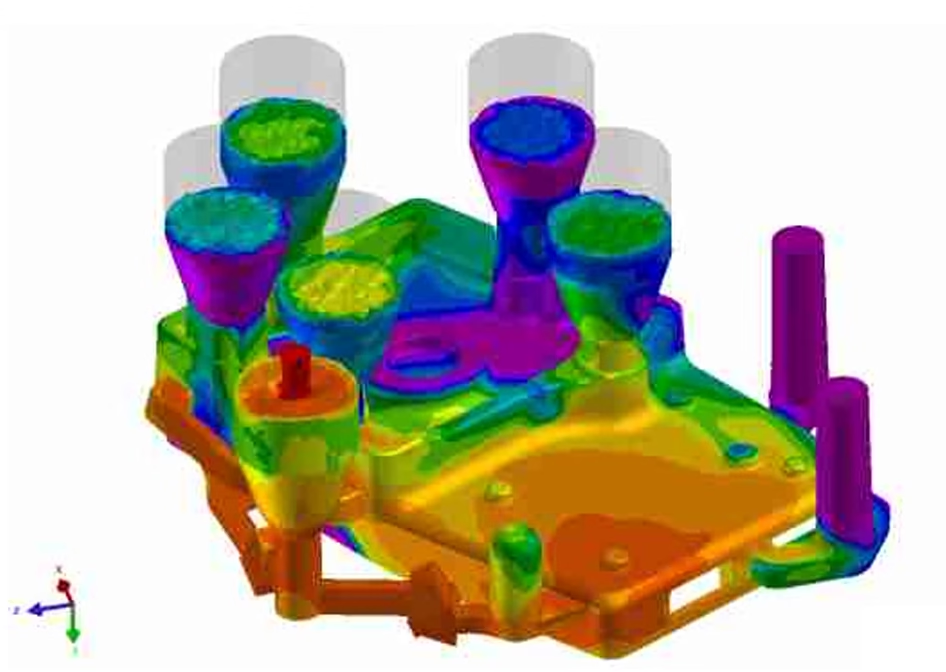

Centrifugal Casting Process

Centrifugal casting, a permanent mold is rotated continuously at high speeds (300 to 3000 rpm) as the molten metal is poured. The molten metal spreads along the inside mold wall, where it solidifies after cooling. The casting is usually a fine-grained casting with an especially fine-grained outer diameter, due to the rapid cooling at the surface of the mold. Lighter impurities and inclusions move towards the inside diameter and can be machined away following the casting.

Benefits

Cylinders and shapes with rotational symmetry are most commonly cast by this technique. Long castings are often produced with the long axis parallel to the ground rather than standing up in order to distribute the effect of gravity evenly.

Thin-walled cylinders are difficult to cast by other means. Centrifugal casting is particularly suited as they behave in the manner of shallow flat castings relative to the direction of the centrifugal force.

Centrifugal casting is also used to manufacture disk and cylinder shaped objects such as railway carriage wheels or machine fittings where grain, flow, and balance are important to the durability and utility of the finished product.

Centrifugal Forming Is Also Far Superior To A Sand Casting And Forging!

- The centrifugal process directional solidification avoids porosity and inclusions associated with centerline shrinkage defects in sand castings.

- The material used to riser the centrifugal process is fed to the casting at 60 times the force used to feed a sand casting.

- The solidification is fed by a huge surface area of high pressure molten metal rather than through a complex network of narrow gates and risers.

- The JCT process uses solid, high chill rate mold materials rather than pressed and glued particulate molds.

- Surface examination of a machined centrifugal can completely qualify a part contrasted with expensive radiographic, ultrasonic or magnetic particle inspection required to determine the soundness of a sand casting.

| FORGING, ETC. | CENTRIFUGAL | |

| Single Source Capabilities | No | Yes |

| Provide Customized Alloys | No | Yes |

| Cost competitive on both small quantity and large | Only at several ton order weights | Both small and large order sizes |

| Raw material cost | Higher | Lower |

| Processing to usable form | No | Yes |

| Capabilities to machine to final size or near form size | No | Yes |

| Micro Structure | Non Denser grain structure | Denser Grain Structure |

| Delivery of product | Typically 10-12 weeks | Typically 4-6 weeks |

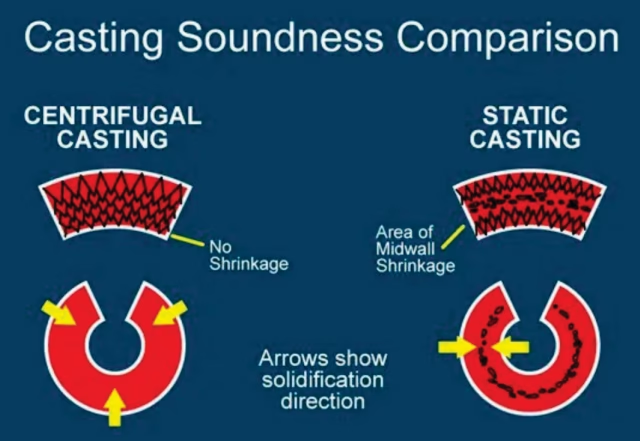

Centrifugal Casting Eliminates Mid-Wall Defects

The centrifugal process does not rely on discrete risers or feed points to ensure the absence of trapped porosity. Rather, the inner diameter remains fully liquid during the solidification process, resulting in a continuous supply of metal to feed areas of contraction. Unlike conventional gravity or static castings that chill from both the inside and outside surfaces and risk trapping mid-wall shrinkage, centrifugal castings solidify from the outside surface inward. The result is a part consistently free of shrinkage cavities, gas pockets, and blowholes.

Applications

Typical parts made by this process are pipes and other parts that are axi-symmetric, It is notably used to cast cylindrical liners and Sleeve valve for piston engines, parts which could not be reliably manufactured otherwise

Industries

Steel Plants

Power Plants

Automobiles

Heavy Duty Machines

Heavy Equipment Utilities

Railways

Rollers

Oil Field Equipment

Features of Centrifugal Casting

- Castings can be made in almost any length, thickness and diameter.

- Different wall thicknesses can be produced from the same mold.

- Eliminates the need for cores.

- Good mechanical properties due to the grain structure formed by centrifugal action.

Other names of Centrifugal castings also known as:

- Sleeves

- Metal Casted Pipes and Tubes

- Metal Rolls

- Spun Cast

- Cylinder Metal Pipe

Method we cast in

- Horizontal Centrifugal Cast

- Vertical Centrifugal Cast

What Our Clients Say About Us

We’ve built long-standing partnerships with engineers, procurement heads, and manufacturers who rely on us for consistent quality, technical precision, and timely delivery.

“Working with Mridini has been a game-changer for our supply chain.”

Their team provided material guidance that improved both casting performance and cost-efficiency. We now rely on them for all our centrifugal castings.

- A. Mehta, Global Pump Manufacturer

“Precision, consistency, and no follow-ups — exactly what you want from a casting partner.”

Mridini's ability to maintain tight tolerances across batches saved us from costly rework. Their quality systems are impressive.

- S. Reddy, Rail Component OEM

“We were struggling with irregular deliveries and surface defects until we switched to Mridini.”

Since then, our rejections have dropped significantly and our lead times are better controlled. Highly recommended.

R. Sharma, Industrial Valves Exporter